Low Voltage for line and Converter Operation

GENERAL PURPOSE SIMOTICS GP

General Purpose motors with an aluminum enclosure are suitable for a wide range of standard drive tasks in the industrial environment. The design and architecture of the motors ensure maximum flexibility and minimum installation costs. Users benefit from integral lifting eyes, screw-on feet, reinforced bearing end shields with optimum mechanical properties and easily accessible terminal boxes. Encoders, brakes and separately driven fans can also be easily added. Thanks to their especially low weight, they are predestined for applications in pumps, fans and compressors. But they can also be reliably deployed in conveyor systems and lifting gear.

In addition to line motors, two converter-optimized motor lines are available for variable-speed converter operation. You can quickly commission your SIMOTICS GP motors based on the motor code for predefined converter parameters.

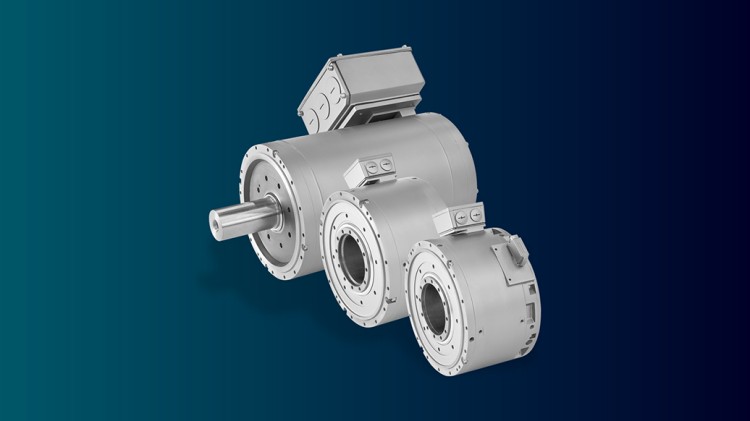

The Severe Duty motors with their rugged gray cast iron housing are the first choice for all important applications in normal industrial settings as well as under harsh ambient conditions. They operate reliably in a temperature range from -50 °C to +60 °C. Degrees of protection up to IP66 and a coating system up to C5 (offshore duty) permit operation in humid, dusty or vibrating environments as well as in aggressive atmospheres. This makes them ideally suited for the petrochemical industry and the general process industry. Their design supports optimum heat dissipation and thus enables very compact dimensions. The modular platform concept offers identical handling to the General Purpose series. This results in a shortened engineering phase and simplified spare parts management. SIMOTICS SD motors cover an integrated performance range from 90 W to 1,000 kW.

SEVERE DUTY SIMOTICS SD

EXPLOSION PROTECTED SIMOTICS XP

SIMOTICS XP CHEMSTAR combines classic CHEMSTAR technology with the SIMOTICS low-voltage motor platform from Siemens. CHEMSTAR has been setting technical standards for explosion-protected motors in the oil & gas and chemical industries for 30 years – and has proven itself 100,000 times over.

- adapted, preconfigured options (not a package!)

- industry-specific Chemstar concept – tailored to the chemical and oil & gas industry

- nameplate (fast access to digital documentation – via QR code)

- optimization through combination with all available variants and options (motors with reduced starting current, premium insulation for systems up to 690 V, motor monitoring by PTC and PT100 for bearings and windings)

- the Chemstar options offer all relevant certificates and are available with a premium insulation system that enables converter operation up to 690V without any type of filter

- other suitable options such as paint finishes up to Class CX according to ISO 12944-2:2018 for the entire spectrum of colors, including non-standard ones, are also available

- consistent performance, easy stocking of spare parts, standardized tools and ordering processes and short delivery times

- reliable and smooth running under extreme conditions – for mains-fed or converter-fed operation.

Going beyond the standard program, sector motors offer a precisely fitting solution to address individual requirements. Every sector has its own requirements when it comes to drive technology. As full-line supplier and based on our many years of experience we precisely understand these requirements. When all is said and done, standard drives from Siemens power almost every industrial sector around the globe.

We are always on the search for innovative solutions to achieve optimum cost effectiveness. This is why, in addition to our standard program, we also offer Definite Purpose motors. These fully satisfy all sector requirements, therefore guaranteeing the highest degree of efficiency.

DEFINITE PURPOSE SIMOTICS DP

FLEXIBLE DUTY SIMOTICS FD

SIMOTICS FD motors optimized for converter operation are the basis for a cost-effective overall system comprising motor and converter with high power density. The cast iron enclosure makes the motor rugged and durable. When operated as variable-speed drive, SIMOTICS FD motors are especially efficient. The combination of SIMOTICS FD motors and SINAMICS low-voltage converters is especially cost effective, as motor and converter are precisely harmonized and coordinated with one another. The motors are based on a leading-edge modular system, which provides the optimum motor to address the widest range of requirements. They are available with different cooling methods – extending all the way to water cooling.

These are energy-efficient induction motors. Siemens offers these motors with aluminum frame in the shaft heights 80 to 160, and power ratings of 90 W to 45 kW. Typical applications include pumps, fans and compressors with special requirements regarding low weight and high efficiency. The Simotics SD Severe Duty motors have a rugged cast-iron frame and cover the power range from 750 W to 315 kW. They are available in shaft heights 100 to 315, and they meet the stricter requirements of the paper and printing industry, as well as the chemicals/petrochemicals industry. The Simotics TN Trans-Standard motors from shaft height 315 and above cover a low-voltage power range from 200 kW to 1,250 kW. They are available for all common operating voltages and cooling types.

TRANSSTANDARD SIMOTICS TN

HIGH TORQUE SIMOTICS HT

The SIMOTICS HT Series HT-direct high-torque motors are permanent-magnet synchronous motors that can provide high torques at low speeds directly at the driven machine. High efficiencies and good power factors can also be achieved at low speeds as a result of the permanent magnet rotors. The SIMOTICS HT Series HT-direct high-torque motors are offered as a harmonized system together with SINAMICS drive converters. The HT-direct motor / SINAMICS drive converter represents a drive solution with a long service lifetime but with low lifecycle costs and high efficiency for applications with low operating speeds.

- High pole design in combination with permanent magnet technology ensures that the space requirement and mass of the motors are lower than for similar asynchronous machines. The slow-running motors of the HT-direct series obviate the need for a gearbox in many cases (reduction in engineering, assembly and maintenance outlay, lower investment and lower operating costs)

- Efficient, optimally matched drive system, SINAMICS converter and HT-direct motor for operation with or without encoders

- Thanks to their long service life (nominal bearing lifetime > 60000 hours), HT-direct high-torque motors are maintenance-free and have a high availability especially for applications in which a gearbox can be omitted

- Environmentally-friendly system (where applicable, no disposal of gearbox oil is necessary; energy-saving drive system)

- Customization is possible

DC motor

DC motors SIMOTICS DC have a compact and modular design and can be used in difficult installation conditions. An extensive range of attachments is available as well as a variety of monitoring and diagnostic options. The high quality of the DC motors is ensured by our comprehensive quality management system. This ensures safe and trouble-free operation. Wherever reliable drive technology and maximum availability are required, the DC motors SIMOTICS DC together with the power converters SINAMICS DCM offer a perfectly matched combination.

Advantages:

- High power density but with low envelope dimensions

- High operational safety and availability through a wide range of diagnostic functions, together with SINAMICS DCM DC converters

- High thermal reserves for continuous and overload duty as a result of the DURIGNIT 2000 insulation system

- Low losses through an extremely high efficiency

- High brush lifetimes using the optimized current commutation system

- Low space requirements for innovative machine solutions

- Low noise construction

- Extremely low vibrations and torque ripple

SIMOTICS DC

Load Break Switches

FUSE SWITCH

DISCONNECTOR-3NP1

Configurator for 3NP1 Fuse Switch Disconnectors.

Thanks to the modular design the 3NP1 Fuse Switch Disconnector allows a multitude of possible switch combinations.

Additional to the selection of ready-to-install versions, this configurator allows you to configurate application specific switches and to select the applicable accessories

Motor for Motion Control

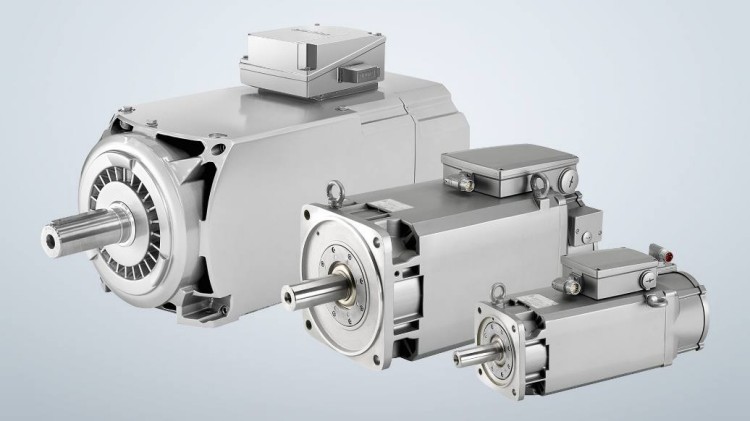

SIMOTICS M-1PH8 motors have been especially designed for use as main drives in production machines and machine tools. In addition to asynchronous and synchronous versions, the motors are also available with synchronous-reluctance technology. Based on a flexible modular kit system, the suitable SIMOTICS M-1PH8 motor can be found for nearly all drive tasks.

For applications where – in addition to the higher drive power – the primary focus is on precise, smooth running characteristics and precise controllability of the axes. Further, you can operate them together with SINAMICS G120 converters which, when compared to standard main motors, extends the applications that they can realize as a result of the wider speed range. This allows them to address new, more compact machine concepts.

MAIN MOTORS SIMOTICS M

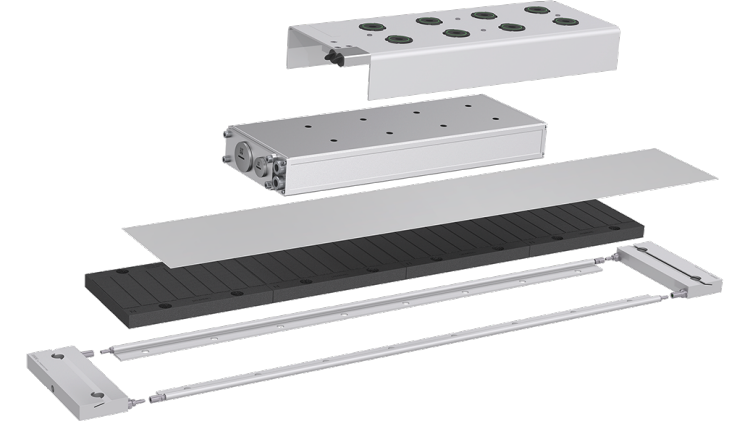

LINEAR MOTORS SIMOTICS L

SIMOTICS L-1FN3 motors are linear drives in compact design featuring superior performance / force density. They are characterized by wear-free force transmission. SIMOTICS L-1FN3 motors fulfill the highest requirements placed on dynamics, contour accuracy and precision and are optimized for operating high-performance machine tools and production machines. Water-cooled SIMOTICS L-1FN3 motors are available in two versions: for peak load and continious load.

The water-cooled SIMOTICS L-1FN3 was specially developed for use in machine tools and has been the proven standard for linear motion for years. Its modular principle offers you a comprehensive range of practically wear-free and therefore low-maintenance motor variants in seven different widths with up to five different lengths and several types of action.

Whether for machine tools, extruder worms or paper rolls – SIMOTICS slow speed permanent-magnet torque motors represent an attractive solution for driving all rotary axis types. They can be completely integrated in machines, without requiring mechanical transmission elements. This reduces the space required, provides maximum flexibility when integrating the motors, minimizes maintenance costs and maximizes availability. Further, the direct mechanical connection results in an increased dynamic performance and control quality in the overall system and ensures a high torque at the optimum speed with high precision – resulting in highly productive machines. Depending on the application, you have the choice between two motor types.

Complete torque motors are permanent magnet AC synchronous motors that are used as a replacement for hydraulic and conventional electric drives, consisting of electric motor and gearbox or belts. They are especially suited for use as direct drives in applications with a torque range of 100 Nm to 7.000 Nm at speeds of 50 to 1.800 rpm.

TORQUE MOTORS SIMOTICS T

Get a customized quote!