SINAMIC V20

SINAMICS V20

The compact SINAMICS V20 is the frequency converter for simple motion sequences. It is characterized by its short commissioning times, easy handling, and energy-saving functions. The converter with its nine sizes covers the power range from 0.12 kW to 30 kW.

Whether in the processing or manufacturing industry: drives make it happen. And drive systems are the perfect place to start when it comes to digitalization. Data from low-voltage motors and low-voltage converters is crucial in ensuring your competitiveness.SINAMICS CONNECT 300 IoT gateway provides a simple plug&play solution to connect SINAMICS low-voltage converters directly to the cloud. It links a SINAMICS V20 to MindSphere without requiring any hardware or software changes – and up to 8 drives can be simultaneously connected.

Simple. Rugged. Efficient.

SINAMICS V20 – The perfect solution for basic applications

SINAMICS G120C

Versatile. User friendly. Compact.

SINAMICS G120C

SINAMICS G120

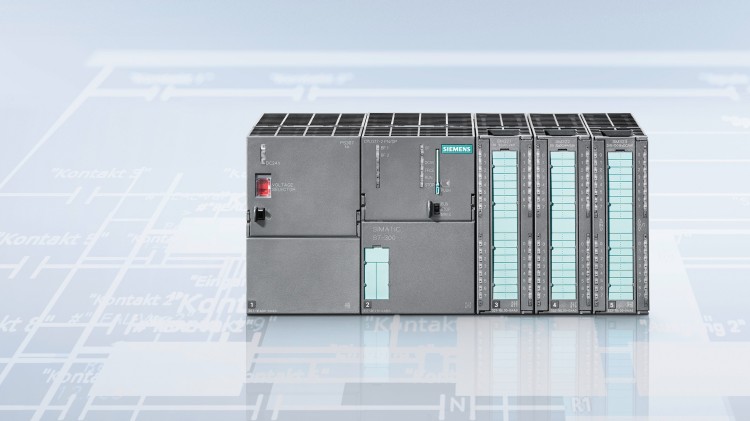

The modular multifunctional frequency converter

The SINAMICS G120 is a modular frequency converter for the most diverse drive tasks. The modular structure of the components and the wide power range from 0.55 to 250 kW ensure that you are always able to assemble the ideal converter for your individual applications and industry branche. This series of converters is available in three voltage variants for connection to 200 V, 400 V and 690 V networks. In addition, the SINAMICS G120 features a comprehensive machine safety package. SINAMICS Startdrive is used for commissioning the safety functions.

Multifunctional. Combinable. Safe.

SINAMICS V90 – The optimized servo drive solution for motion control applications

The drive system comprises the SINAMICS V90 servo converter and the SIMOTICS S-1FL6 servo motor. The system features eight converter frame sizes and seven motor shaft heights to cover a power range of 0.05 to 7.0 kW for operation in single-phase and three-phase networks. It can be integrated easily via PTI, PROFINET, USS or Modbus RTU. The SINAMICS V90 servo drive system enables a host of simple motion control tasks to be implemented cost-efficiently and conveniently with the focus being on dynamic motion and processing.

Simple. Precise. System-based.

SINAMIC V90

SINAMICS G110M

SINAMICS G110M distributed gearmotor-integrated drive

As a member of the SINAMICS G series of variable speed drives, the SINAMICS G110M distributed drive, with a high degree of protection (up to IP66), has a modular design, comprised of a Control Unit and Power Module. It is designed to be used as a drive integrated in SIMOGEAR geared motors and SIMOTICS GP motors, but can also be used as a wall-mounted drive in other distributed applications. A Match Made for Conveyors: SIMOGEAR geared motors with SINAMICS G110M motor-integrated drives provide the perfect solution to any conveyor-related challenge.

SINAMICS G110M – open-loop and closed-loop control of induction motors in a wide range of industrial applications

SINAMICS G110D V/hz distributed drive

SINAMICS G110D is a simpler version of the higher-performance SINAMICS G120D, offering many of the same features. This v’hz distributed drive solution combines improved functionality, increased energy efficiency, a smaller footprint, lower total cost-of-ownership, and enhanced usability in a single drive. Perfect for use as a conveyor drive, it is ideal for installation in close proximity to motors located throughout facilities where dust and water ingression are a concern. The SINAMICS G110D is suitable for open-loop induction motors in a wide range of industrial applications and systems in which a drive is operated in a distributed configuration. Connected to AS-i or locally without a bus system, the drive may also be connected to PROFIBUS via the DP/AS-i Link.

SINAMICS G110D – distributing flexibility, economy, smarts

SINAMICS G110D / G120D

SINAMICS G110D / G120D

The universal converter for high power ratings

Chassis-, and Cabinet Units SINAMICS G130 / G150

SINAMICS G130 chassis units and SINAMICS G150 cabinet units have been designed for variable-speed drives in machine building and plant construction. They have been specially tuned to the requirements of drives with quadratic or constant load characteristics with medium performance requirements without regenerative feedback. The control accuracy of the sensorless vector control is suitable for most applications, and additional actual speed value encoders are therefore superfluous. SINAMICS G130/G150 offer an economical drive solution which can be matched to the respective customer requirements by a wide range of components and options.

SINAMICS G130 | SINAMICS G150 | |

Supply voltage and output range | 3 AC 380 to 690 V, 75 to 800 kW | 3 AC 380 to 690 V, 110 to 2700 kW |

Frequency | 47 to 63 Hz | 47 to 63 Hz |

Control modes | Vector control with encoder or V/f control | Vector control with encoder or V/f control |

The specific converter for the oil & gas, chemical and process industries

Feature | Value |

|---|---|

Line voltage and output range | 3 AC 230 – 690 V; 2.2 up to 6600 kW |

Line frequency and output frequency | 47 to 63 Hz; 0 to 250 Hz (dependent on the power) |

Control modes | Vector control with encoder or U/f control |

SINAMICS G180

SINAMICS S110

The SINAMICS S110 servo drive is designed for connection to both synchronous servomotors and asynchronous (induction) motors. It supports all the most popular types of encoder.A variety of fieldbus interfaces is provided for linking the unit to a higher-level control system. Alternatively, it can be controlled via ±10 V and a pulse direction interface.

The so-called basic positioner (EPos) is an integral component of SINAMICS S110. It provides a simple method of solving positioning tasks.

Flexible in application

SINAMICS S110 is a flexible, versatile system.Synchronous servomotors and asynchronous (induction) motors with outputs up to 132 kW can be used to implement rotary or linear axes. DRIVE-CLiQ motors can be connected simply by means of the integrated DRIVE-CLiQ interface. This means that the electronic rating plate of the motor is easy to read out, reducing the engineering time and cost involved in commissioning the drive.

Furthermore, the SINAMICS S110 features an integrated encoder interface for optional use. It is capable of evaluating HTL/TTL and SSI encoders.

SINAMICS S120M distributed servo drive

The modular SINAMICS S120 drive system has been expanded to include the distributed SINAMICS S120M version. This involves a compact ready-to-connect drive unit consisting of a synchronous servomotor with multiturn absolute encoder and integrated power unit (motor module). The SINAMICS S120M gives the option to move the power unit out of the control cabinet where it is directly integrated with the motor on the driven servo axis. This provides advantages and a high degree of flexibility regarding existing and new machine concepts. The innovative hybrid cable reduces cabling and connects back to the central SINAMICS S120 components utilizing the adapter module 600 (AM600).

Efficient. Flexible. Compatible.

SINAMICS S120M

SINAMICS S150

The cabinet unit converter for demanding applications with energy recovery.

SINAMICS S150

The compact SINAMICS S150 cabinet units are designed for variable speed drives in machine building and plant engineering. They are particularly suitable for use with variable speed drives with high demands on dynamics and speed accuracy, frequent braking cycles with high braking energies and 4-quadrant operation. SINAMICS S150 offers high-performance speed control with high accuracy and dynamics. The inverter cabinet units are available for the power range from 75 kW to 1200 kW.

Line voltage | 3 AC 380 up to 480 V 3 AC 500 up to 690 V |

|---|---|

Power range | 110 up to 800 kW 75 up to 1200 kW |

Degree of protection | IP20 (Standard), optional IP21/IP23/IP43 and IP54 |

Control mode | Vector control with and without encoder or U/f control |

Get a customized quote!